- Materials scientists have created a glass nanolattice structure five times lighter and four times stronger than steel.

- They call the new material the strongest known for its given density.

- The use of a DNA structure and thin, flawless glass is the secret sauce.

If Iron Man ever needs a new suit, he’s got options—thanks to a new material created by a team of researchers using a DNA structure and flawless glass.

This high-strength, lightweight, nano-architected silica is now the strongest known material for its given density. It comes in at five times lighter and four times stronger than steel, according to the study published in Cell Reports Physical Science.

Marrying lightweight strength in materials is the never-ending push-pull effort. But these often mutually exclusive properties may have a happy union thanks to a DNA structure and glass, according to the team.

And it was inspired by, of all things, Iron Man’s suit. “I am a big fan of Iron Man movies, and I have always wondered how to create a better armor for Iron Man,” Oleg Gang, nanomaterials scientists at Columbia University, said in a news release. “It must be very light for him to fly faster. It must be very strong to protect him from enemies’ attacks. Our new material is five times lighter but four times stronger than steel. So, our glass nanolattices would be much better than any other structural materials to create an improved armor for Iron Man.”

But glass? That doesn’t seem the obvious choice.

The researchers, which include scientists from the University of Connecticut, Columbia University, and Brookhaven National Lab, say glass—when flawless, that is—actually provides an ideal avenue toward crafting a new type of material.

Iron, for example, can handle 7 tons of pressure per square centimeter. A flawless cubic centimeter of glass, though, can take on 10 tons of pressure (the scientists say that is more than three times the pressure that imploded Oceangate’s Titan submersible). And with steel weighing a dense 7.8 grams per cubic centimeter, the strength comes with a heavy price.

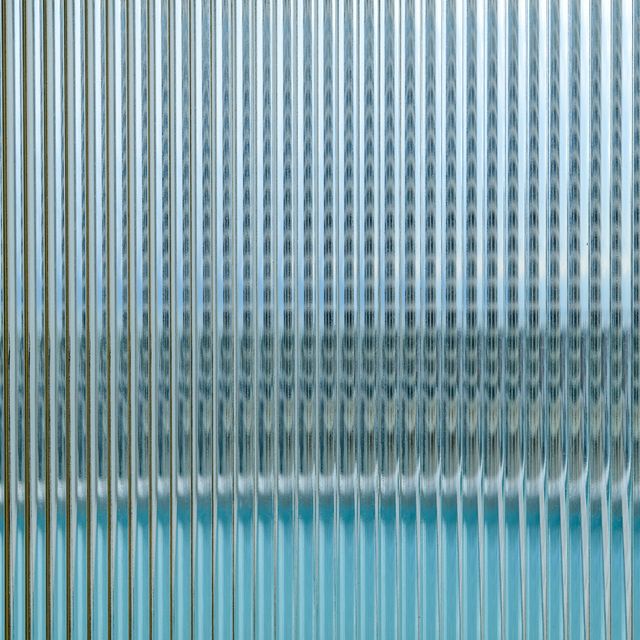

Glass’s reputation for shattering easily is actually a result of any flaws present in the material—flawlessness is what brings lightweight strength. And to create flawless glass, the team used a sample less than a micrometer thick. At that thickness, glass is almost always flawless, and is much less dense than other metals and ceramics.

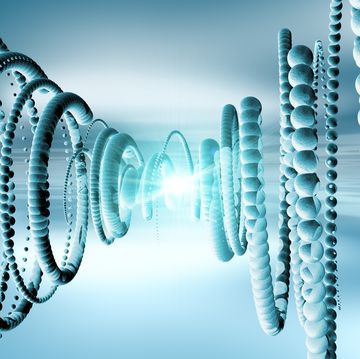

The team then built a DNA lattice and coated it with a glass-like material only a few hundred atoms thick. Coating the DNA strands left empty space in portions of the material volume. This DNA skeleton reinforced the thin, flawless coating of glass for strength, and the voids made it lighter.

The study says that the coordination of the nano thin silica elements offers an “effective strategy for the fabrication of nano architected materials with superior mechanical properties.” And the team believes they’re just getting started.

“The ability to create designed 3D framework nanomaterials using DNA and mineralize them opens enormous opportunities for engineering mechanical properties,” Gang says. “But much research work is still needed before we can employ it as a technology.”

The team is now employing the same DNA structure design in further materials development, but has switched to stronger carbide ceramics for glass. They will also experiment with different DNA structures to see which makes the material strongest.

Maybe Iron Man will soon have a friend: Glass Man.

Tim Newcomb is a journalist based in the Pacific Northwest. He covers stadiums, sneakers, gear, infrastructure, and more for a variety of publications, including Popular Mechanics. His favorite interviews have included sit-downs with Roger Federer in Switzerland, Kobe Bryant in Los Angeles, and Tinker Hatfield in Portland.