Cornell School Board; Metal cutter another way to prepare kids for careers

A small show-and-tell video Nov. 28, showed the Cornell School Board members what a metal laser cutter can do, once it is installed in the district shop, which was very impressive to board treasurer Stephanie Seidlitz. The new piece of equipment was donated and will help get the tech ed students exposed to a potential career(s). Photo by Ginna Young

By Ginna Young

In effort to “beef up” the tech ed department, Cornell School District educators reached out to a few local industry leaders, to find out what would work in the fab lab and what equipment is lacking on Cornell’s end.

Craig Braaten, assistant principal, reported on their findings Nov. 28, during the regular school board meeting. At first, the school was considering a fiber laser cutter for metal, but plans for that halted when they discovered such a machine comes with a hefty price tag of $600,000.

Although Braaten is currently writing a grant, it’s not even close to what they need to buy the cutter. After a few more connections were made, Cornell was informed that a laser cutter would be donated.

“The only issue with this laser, is it’s ginormus,” said Braaten.

The 2011 machine was originally purchased for $150,000 and has a 24-foot footprint, but Cornell will find some space to set it up in. All the school has to do, is pay for shipping from Chippewa Falls. There are also 4x8 sheets of stainless steel “scrap” metal, that some companies are willing to donate if Cornell comes to get it.

Braaten is also continuing to write the grant for a press break that can bend metal.

“We’re excited to get it in,” he said. “This equipment is what drives kids into these fields. The amount of work in the Chippewa Valley is insane.”

The goal of the district is to expose kids to new things, where they can walk right out and get a job after graduation.

“With a machine like this…if you can deal with metal, you can deal with artistic stuff…there’s a million things you can do with this,” said middle/high school principal Dave Elliott.

However, Elliott says the learning curve will take some time and that they need the kids to buy in. Younger students often pick up technology faster, so they need to be exposed early on. Braaten says the machines Cornell has/will have open(ed) the way for students to choose the direction they want to go, whether that be as a designer, operator or in sales.

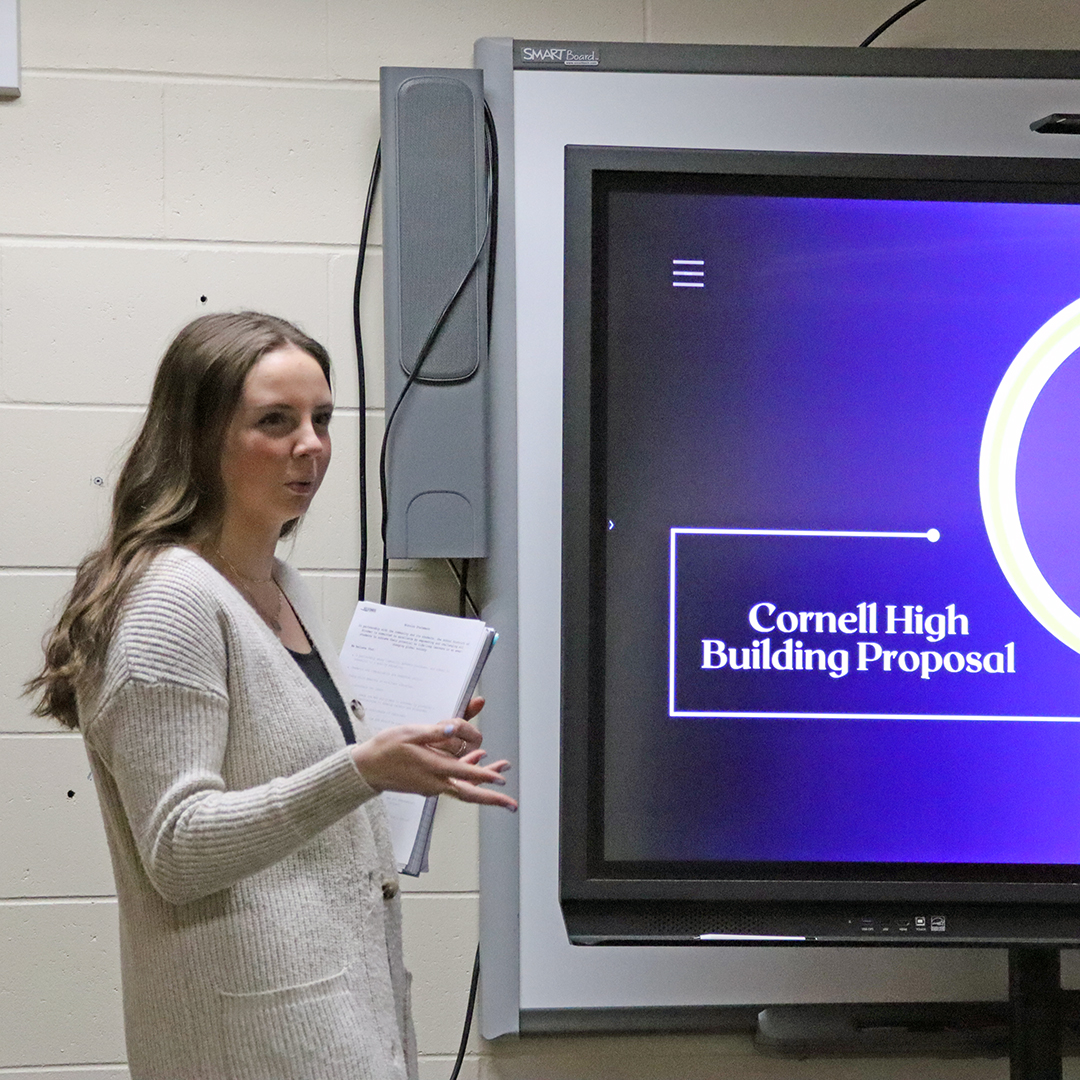

“I’m so proud of the fact that you guys are going after this stuff and that you’re giving these kids these opportunities,” said board treasurer Stephanie Seidlitz. “This is impressive.”